| Availability: | |

|---|---|

| Quantity: | |

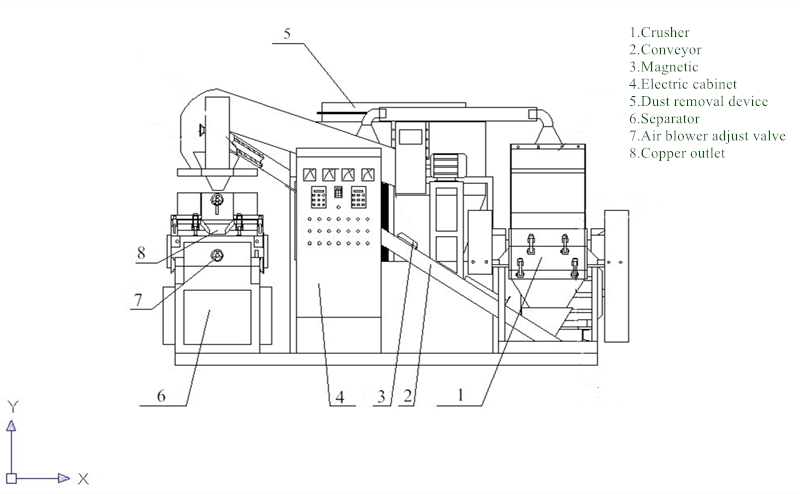

KLG-600S2

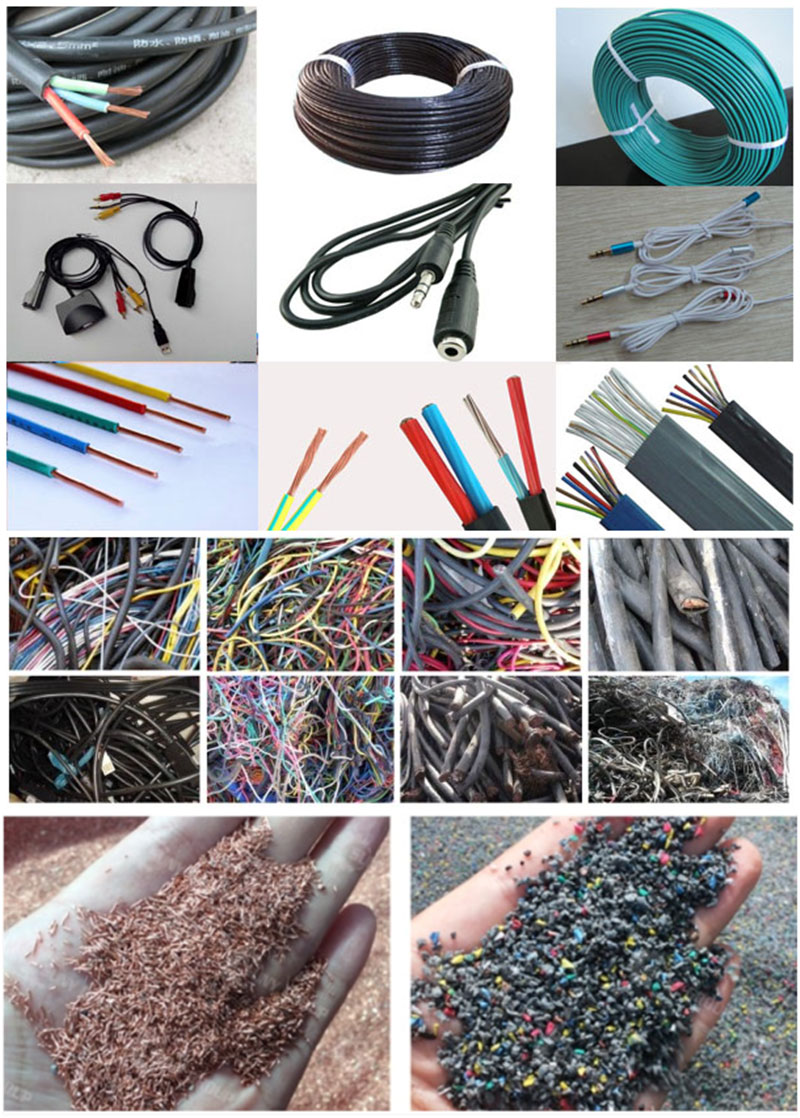

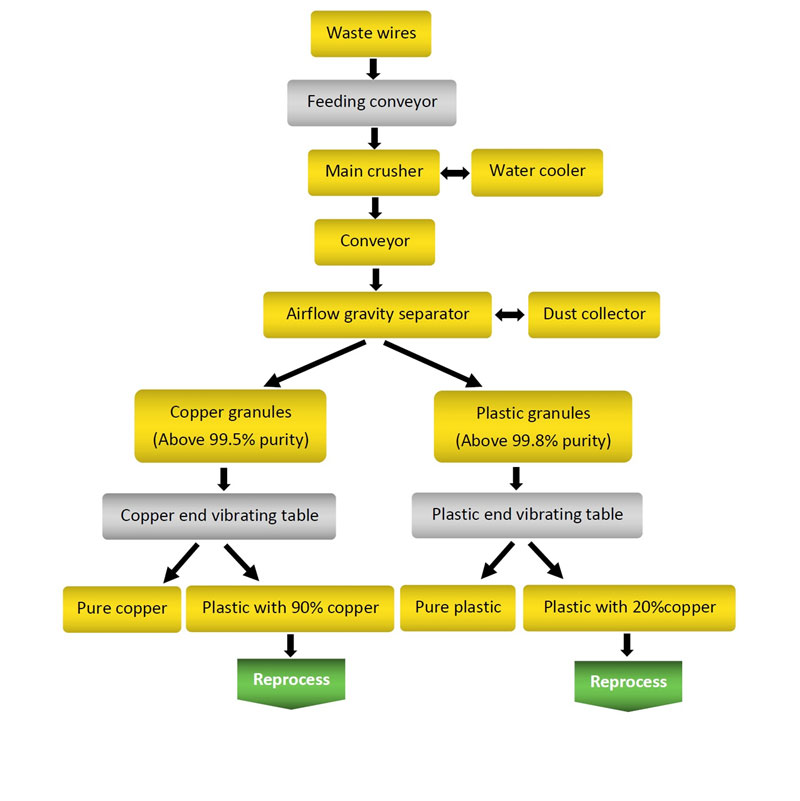

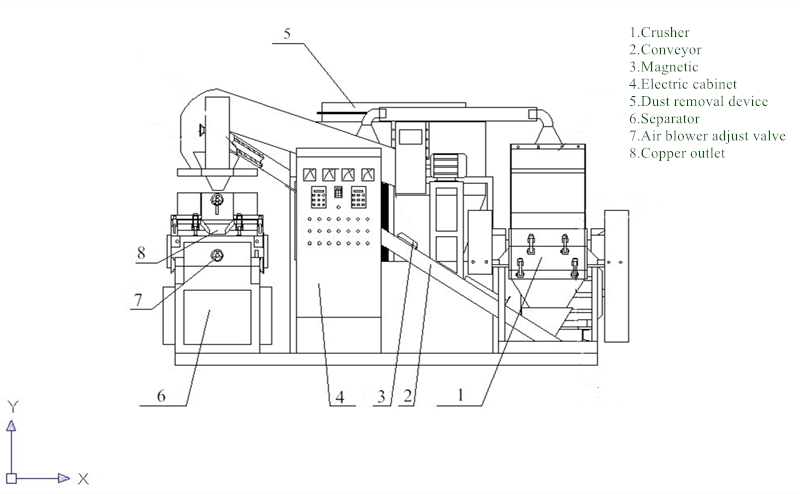

KLG-600S2 Upgrade Upgrade Complete Line of Waste Copper Cable Granulator Separating Machine (we generally call it wire granulator machine) is professional line for scrap wire yard or recycling plant. It can recovery 99.5% copper and plastic from the scrap wires with dry airflow and gravity separator (copper core within 30mm),such as automobile wires, car bottom wires, motorcycle wires, computer wires and communication cable, etc.

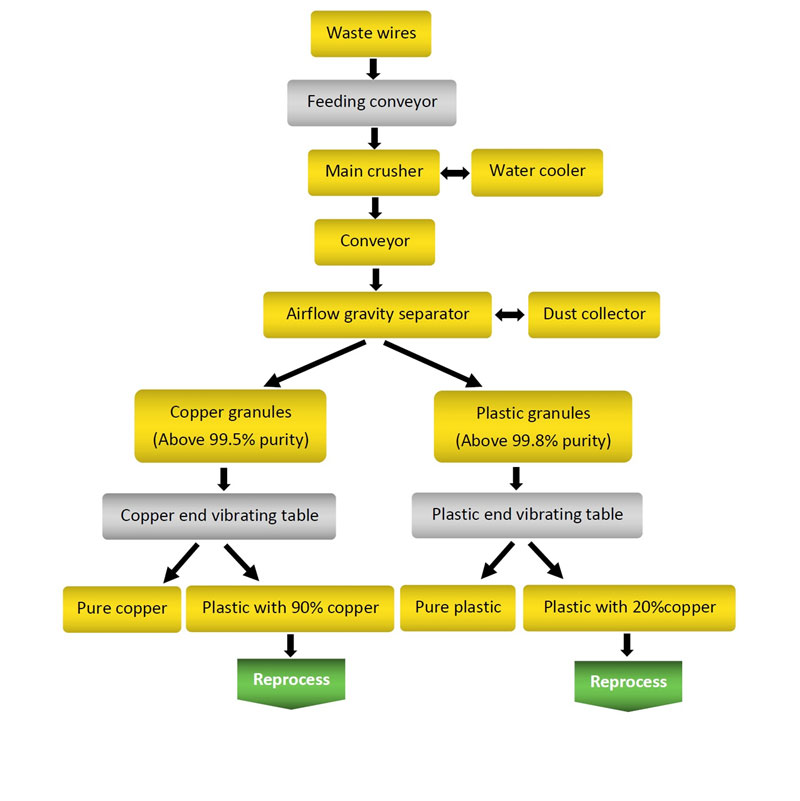

With complete set of Scrap Wire Machine Line, you can process the waste copper wire and cables to tiny copper and plastic granules which purity up to 99.9% the best. There are feeding conveyor,crusher,air separator, magnetic iron suction device, end vibrating tables and electrostatic separator for ensure the best separation work.

It is the hottest model with medium production capacity (350-600kg/hour). Some ready machine in stock, can make delivery within 7days. If you have below waste wires, please contact us for a perfect solution.

Crushing→Airflow separating→Dust collecting→Iron removing (optional)→Vibrating tables (optional) → Electrostatic Separating (optional)

1. Compact structure, reasonable layout, easier installation and less space.

2. PLC control to ensure the evenly feeding, efficient & stable running.

3. Special designed crusher makes less noise but bigger output.

4. The sorting rate of air separator above 99%. With additional vibrating table can reach 99.9%.

5. Dust collection device for creating clean operating space.

6. Water cooler tank for cooling crusher body.

KLG-600S2 Upgrade Upgrade Complete Line of Waste Copper Cable Granulator Separating Machine (we generally call it wire granulator machine) is professional line for scrap wire yard or recycling plant. It can recovery 99.5% copper and plastic from the scrap wires with dry airflow and gravity separator (copper core within 30mm),such as automobile wires, car bottom wires, motorcycle wires, computer wires and communication cable, etc.

With complete set of Scrap Wire Machine Line, you can process the waste copper wire and cables to tiny copper and plastic granules which purity up to 99.9% the best. There are feeding conveyor,crusher,air separator, magnetic iron suction device, end vibrating tables and electrostatic separator for ensure the best separation work.

It is the hottest model with medium production capacity (350-600kg/hour). Some ready machine in stock, can make delivery within 7days. If you have below waste wires, please contact us for a perfect solution.

Crushing→Airflow separating→Dust collecting→Iron removing (optional)→Vibrating tables (optional) → Electrostatic Separating (optional)

1. Compact structure, reasonable layout, easier installation and less space.

2. PLC control to ensure the evenly feeding, efficient & stable running.

3. Special designed crusher makes less noise but bigger output.

4. The sorting rate of air separator above 99%. With additional vibrating table can reach 99.9%.

5. Dust collection device for creating clean operating space.

6. Water cooler tank for cooling crusher body.

Model: KLG-600S1 Upgrade Cable Granulator Separator Copper Wire Recycling Machine | |

Cable input limitation | 0.2-28mm |

Output | 350-600kg/hour |

Total power | 43kw |

Machine weight | Around 3500kg |

Overall size | 390cm*200cm*225cm |

Voltage | 380V/50Hz/3Phase (Customized) |

Shipping | 1*20GP container |

Model: KLG-600S1 Upgrade Cable Granulator Separator Copper Wire Recycling Machine | |

Cable input limitation | 0.2-28mm |

Output | 350-600kg/hour |

Total power | 43kw |

Machine weight | Around 3500kg |

Overall size | 390cm*200cm*225cm |

Voltage | 380V/50Hz/3Phase (Customized) |

Shipping | 1*20GP container |