| Availability: | |

|---|---|

| Quantity: | |

Y81S-4000

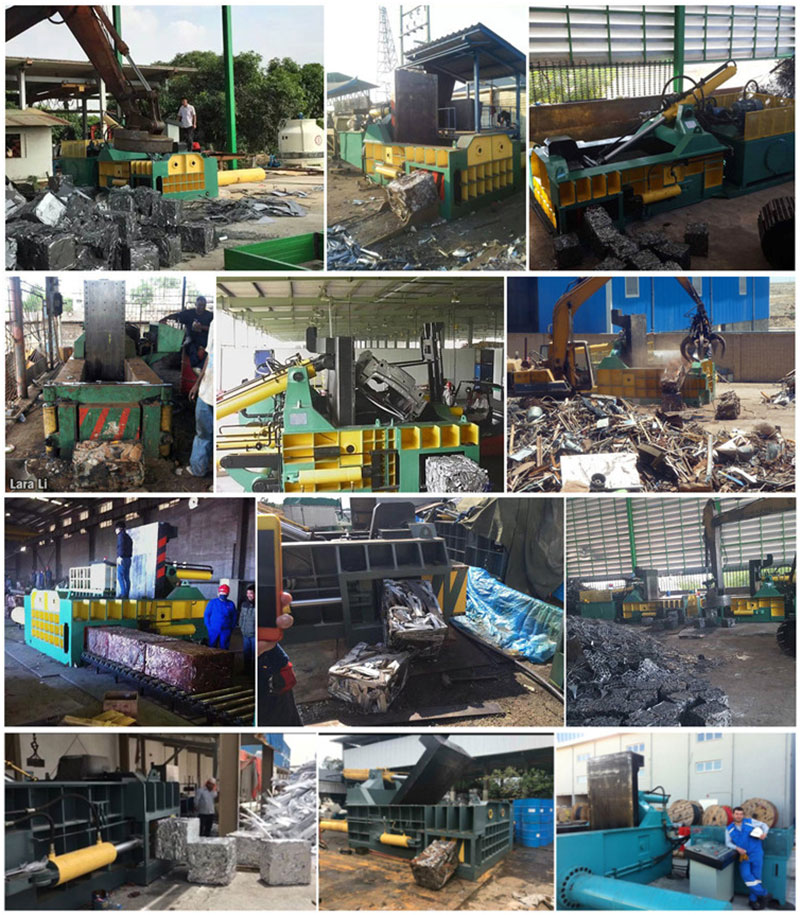

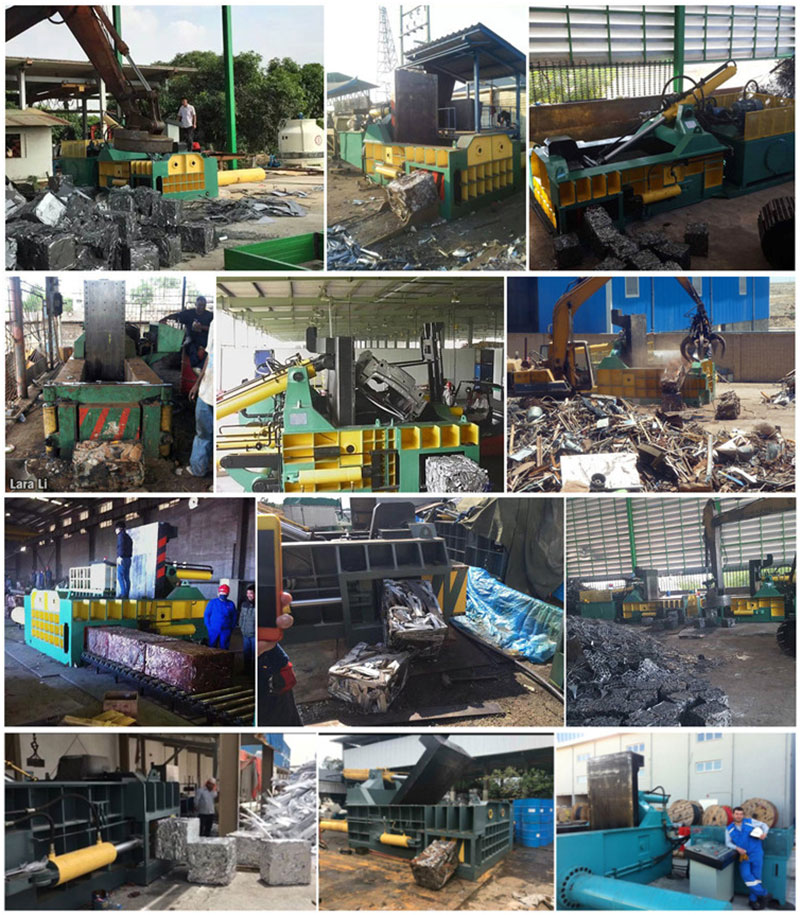

Y81S-4000 Double Main Cylinders Metal Scrap Bundling Machine is capable of extruding various metal waste,steel turnings,REBARS and alloy, waste copper,aluminum profiles,stainless steel, scrapped car body and other shapes of metals scrap. It makes high density bales, square,octagon, cylinder different shapes are available.

By this way, the cost of transportation and burning loss can be reduced a lot. It also makes much efficient storage.

Double Main Cylinders Metal Scrap Bundling Machine for Rebars is mainly used in metal plants,recycling yards,waste recovery and metal refining industry. Size of compressing chamber and finished bale can be customized.

This is the hottest model for medium or large scrap yards. With double biggest main cylinders, it requires less cycle time even with such wide chamber size. Fully automatic running with PLC system & remote control.

1) Hydraulic drive, no need special foundataion

2) Compact design, installation free and less floor space

3) Pressing force ranges from 400T to 1000T

4) Customized bale & chamber box size

5) Hardox steel NM500 for whole wearing plate.

◆ Fe, Al, Cu, Cr-Ni Scraps

◆ Ferrous and non-ferrous

◆ Aluminium Extrusions, UBC, Profiles

◆ Rebars, Sheets, Buckets and other Mixed Scraps

Y81S-4000 Double Main Cylinders Metal Scrap Bundling Machine is capable of extruding various metal waste,steel turnings,REBARS and alloy, waste copper,aluminum profiles,stainless steel, scrapped car body and other shapes of metals scrap. It makes high density bales, square,octagon, cylinder different shapes are available.

By this way, the cost of transportation and burning loss can be reduced a lot. It also makes much efficient storage.

Double Main Cylinders Metal Scrap Bundling Machine for Rebars is mainly used in metal plants,recycling yards,waste recovery and metal refining industry. Size of compressing chamber and finished bale can be customized.

This is the hottest model for medium or large scrap yards. With double biggest main cylinders, it requires less cycle time even with such wide chamber size. Fully automatic running with PLC system & remote control.

1) Hydraulic drive, no need special foundataion

2) Compact design, installation free and less floor space

3) Pressing force ranges from 400T to 1000T

4) Customized bale & chamber box size

5) Hardox steel NM500 for whole wearing plate.

◆ Fe, Al, Cu, Cr-Ni Scraps

◆ Ferrous and non-ferrous

◆ Aluminium Extrusions, UBC, Profiles

◆ Rebars, Sheets, Buckets and other Mixed Scraps

Model | Main cylinder force (tons) | Feed box size (mm) | Bale size (mm) | Bale weight (kgs) | Capacity (ton/hour) | Power (kw) |

Y81S-3150 | 315 | 3000*2500*1200 | 600*600 | 500-700 | 6-8 | 45*2 |

Y81S-4000 | 400 | 3500*3000*1300 | 600*600 | 700-1000 | 7-10 | 45*2 |

Y81S-5000 | 500 | 3500*3000*1300 | 650*650 | 1000-1200 | 8-12 | 45*3 |

Y81S-6300 | 630 | 3500*3000*1300 | 700*700 | 1200-1500 | 15-18 | 45*3 |

One set Scrap Ferrous Metal Recycling Baler Machine can be loaded in one 40" FR container and one 40"GP or Bulk carrier | ||||||

Model | Main cylinder force (tons) | Feed box size (mm) | Bale size (mm) | Bale weight (kgs) | Capacity (ton/hour) | Power (kw) |

Y81S-3150 | 315 | 3000*2500*1200 | 600*600 | 500-700 | 6-8 | 45*2 |

Y81S-4000 | 400 | 3500*3000*1300 | 600*600 | 700-1000 | 7-10 | 45*2 |

Y81S-5000 | 500 | 3500*3000*1300 | 650*650 | 1000-1200 | 8-12 | 45*3 |

Y81S-6300 | 630 | 3500*3000*1300 | 700*700 | 1200-1500 | 15-18 | 45*3 |

One set Scrap Ferrous Metal Recycling Baler Machine can be loaded in one 40" FR container and one 40"GP or Bulk carrier | ||||||

◆ No matter before or after deal, you will get 24 hours online service.

◆ Any needed machine parts can be supplied with professional guiding and competitive price.

◆ Engineer can be dispatched abroad for installation and maintenance or remote guidance by video.

◆ Due to quality issue, parts provided freely during warranty.

◆ With more than 10 years manufacturering experience, we provide consulting, product selection, design drawings, manufacturing, installation, training, maintenance and other technical support.

◆ No matter before or after deal, you will get 24 hours online service.

◆ Any needed machine parts can be supplied with professional guiding and competitive price.

◆ Engineer can be dispatched abroad for installation and maintenance or remote guidance by video.

◆ Due to quality issue, parts provided freely during warranty.

◆ With more than 10 years manufacturering experience, we provide consulting, product selection, design drawings, manufacturing, installation, training, maintenance and other technical support.