| Availability: | |

|---|---|

| Quantity: | |

KLG-800S

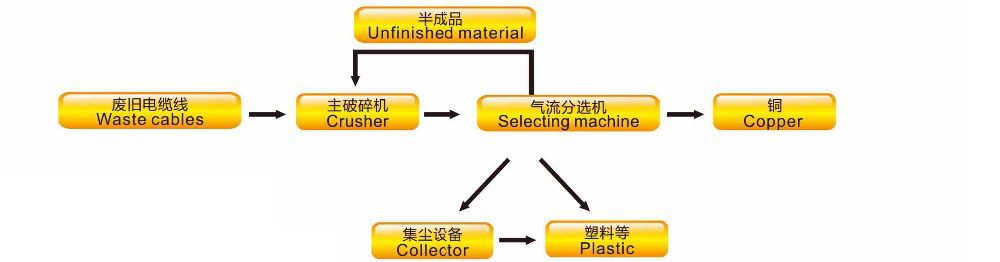

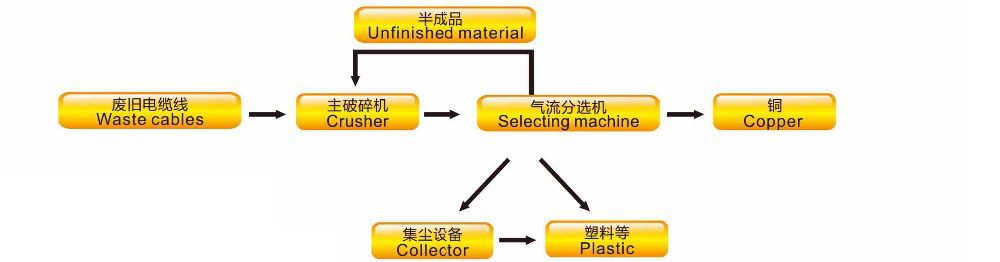

KLG-800S wire granulator machine is professional line for recycling waste wires. It is for grinding and separating the pvc and copper. Work with dry type air separating device, especially for those wire which not suitable for stripping (generally copper core within 25mm), such as automobile wires, car bottom wires, motorcycle wires, computer wires and communication cable, etc. With KLG-800S wire granulating machine, you can recycle the waste copper wire and cables to get tiny copper and plastic granulations.

Crushing→Air separating→Dust collecting→Iron removal (optional)→Secondary Separating (Optional)

1. Compact structure, reasonable layout, easy installation and transportation.

2. PLC control to ensure the evenly feeding, efficient running also stable performance.

3. Special designed crusher makes less noise but bigger output.

4. The sorting rate of air separator above 99%.

5. Additional vibrating table for secondary separation which makes purer copper/plastic.

6. Dust collection device for creating clean operating space.

Model: KLG-800S scrap wire granulator machine | |

Cable input limitation | 0.2-30mm |

Output | 700-1200kg/hour |

Total power | 76kw |

Machine weight | Around 5800kg |

Overall size | 720cm*750cm*225cm |

1.Conveyor #1 | 6.Electric cabinet | 11.Plastic outlet |

2.Crusher | 7.Copper outlet | 12.After dedusting |

3.Water cooler | 8.Vibrating table for copper | 13.Vibrating table for plastic |

4.Pre-dedusting | 9.Separator | 14.Dust collecting bag |

5.Conveyor #2 | 10.Air blower adjust valve | 15.Dust removal |

KLG-800S wire granulator machine is professional line for recycling waste wires. It is for grinding and separating the pvc and copper. Work with dry type air separating device, especially for those wire which not suitable for stripping (generally copper core within 25mm), such as automobile wires, car bottom wires, motorcycle wires, computer wires and communication cable, etc. With KLG-800S wire granulating machine, you can recycle the waste copper wire and cables to get tiny copper and plastic granulations.

Crushing→Air separating→Dust collecting→Iron removal (optional)→Secondary Separating (Optional)

1. Compact structure, reasonable layout, easy installation and transportation.

2. PLC control to ensure the evenly feeding, efficient running also stable performance.

3. Special designed crusher makes less noise but bigger output.

4. The sorting rate of air separator above 99%.

5. Additional vibrating table for secondary separation which makes purer copper/plastic.

6. Dust collection device for creating clean operating space.

Model: KLG-800S scrap wire granulator machine | |

Cable input limitation | 0.2-30mm |

Output | 700-1200kg/hour |

Total power | 76kw |

Machine weight | Around 5800kg |

Overall size | 720cm*750cm*225cm |

1.Conveyor #1 | 6.Electric cabinet | 11.Plastic outlet |

2.Crusher | 7.Copper outlet | 12.After dedusting |

3.Water cooler | 8.Vibrating table for copper | 13.Vibrating table for plastic |

4.Pre-dedusting | 9.Separator | 14.Dust collecting bag |

5.Conveyor #2 | 10.Air blower adjust valve | 15.Dust removal |